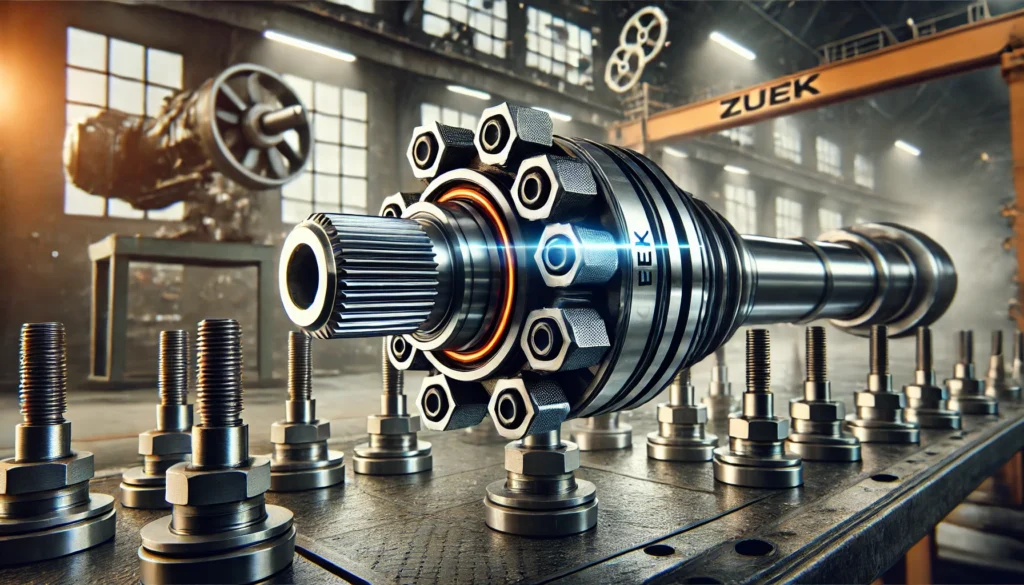

Zuek Fasteners Drive Shaft in Action: High-Performance and Vibration-Resistant

Introduction

In the world of mechanical engineering, fasteners play a pivotal role in ensuring the integrity and safety of rotating components. One of the most innovative solutions in this space is the Zuek Fasteners Drive Shaft. Designed for high-performance applications, Zuek fasteners offer unmatched reliability, especially in environments prone to vibration and mechanical stress.

This comprehensive guide explores the key features, types, installation procedures, maintenance tips, and troubleshooting methods related to Zuek fasteners drive shafts. Whether you’re an industry professional, a mechanical enthusiast, or someone looking to upgrade your equipment, this guide will provide valuable insights.

Understanding Drive Shafts

A drive shaft is a mechanical component that transmits torque and rotational energy from an engine to the wheels or other machinery parts. It plays a crucial role in vehicles, industrial machines, and aerospace applications. The drive shaft connects different parts of a drivetrain while compensating for alignment changes caused by movement or vibrations.

Key Components of a Drive Shaft

- Universal Joints (U-Joints): Allow flexibility and accommodate angular changes.

- Slip Yokes: Adjust for length variations during operation.

- Center Support Bearings: Provide additional support, especially in longer drive shafts.

These components rely heavily on secure fasteners like Zuek fasteners to maintain optimal performance.

Introduction to Zuek Fasteners

Zuek fasteners are specialized mechanical fasteners engineered for high-stress environments. They are known for their quarter-turn locking mechanism, which provides a secure, vibration-resistant hold while allowing quick installation and removal.

Unique Features and Benefits

- High Vibration Resistance: Prevents loosening in dynamic environments.

- Durability: Built with corrosion-resistant materials.

- Ease of Installation: Requires minimal tools for assembly and disassembly.

Compared to traditional fasteners, Zuek fasteners offer superior performance in terms of reliability and ease of maintenance.

Types of Zuek Fasteners

Zuek fasteners come in various designs tailored to specific applications:

- Standard Quarter-Turn Fasteners: Ideal for general automotive and industrial use.

- Self-Ejecting Fasteners: Designed with springs to prevent fastener loss during disassembly.

- High-Torque Fasteners: Suitable for heavy-duty machinery where extreme forces are involved.

- Corrosion-Resistant Fasteners: Perfect for marine and aerospace environments where exposure to moisture is high.

| Type | Application | Key Feature |

|---|---|---|

| Standard | Automotive, Industrial | Quick locking mechanism |

| Self-Ejecting | Aerospace, Marine | Prevents fastener loss |

| High-Torque | Heavy Machinery | Withstands extreme forces |

| Corrosion-Resistant | Marine, Chemical Plants | High resistance to rust |

Integration of Zuek Fasteners in Drive Shaft Assemblies

In drive shaft assemblies, Zuek fasteners play a critical role in maintaining structural integrity. They are commonly used in:

- U-Joint Connections: Securing universal joints, ensuring flexibility and torque transfer.

- Slip Yokes: Providing secure attachment while allowing axial movement.

- Center Support Bearings: Keeping the drive shaft properly aligned.

Their precision engineering ensures minimal vibration, reduced wear, and enhanced performance.

Installation Procedures

Pre-Installation Preparations

Before starting the installation, gather the necessary tools:

- Torque wrench

- Safety gloves

- Lubricants (if required)

Ensure the drive shaft components are clean and free from debris.

Step-by-Step Installation Guide

- Align the Components: Place the drive shaft and ensure all parts are correctly aligned.

- Insert the Fastener: Insert the Zuek fastener into its designated slot.

- Secure the Fastener: Turn the fastener 90 degrees to lock it in place.

- Check Torque Specifications: Use a torque wrench to ensure the fastener meets the required torque level.

Common Installation Challenges and Solutions

- Misalignment: Double-check component positioning before securing.

- Loose Fasteners: Ensure proper torque application to prevent loosening.

Maintenance and Inspection

Regular maintenance of Zuek fasteners drive shafts is crucial for longevity.

Inspection Protocols

- Visual Check: Look for signs of wear, corrosion, or damage.

- Physical Test: Ensure fasteners are tight and secure.

Lubrication Requirements

While many Zuek fasteners are self-lubricating, some applications may require periodic lubrication to prevent rust.

Replacement Criteria

Replace fasteners if you notice:

- Significant corrosion

- Visible cracks or deformation

- Difficulty in securing properly

Advantages of Using Zuek Fasteners in Drive Shafts

- Enhanced Vibration Resistance: Reduces the risk of fastener loosening.

- Improved Durability: Designed for long-term use in harsh environments.

- Simplified Maintenance: Quick installation and removal save time.

Industry Applications

Zuek fasteners are versatile and used across various industries:

- Automotive: Passenger vehicles, trucks

- Aerospace: Aircraft components

- Heavy Machinery: Construction and mining equipment

- Marine: Boats and underwater vehicles

Safety Considerations

- Wear Protective Gear: Gloves and safety glasses during installation.

- Torque Specifications: Follow guidelines to avoid over-tightening.

- Emergency Procedures: Know how to handle fastener failure safely.

Troubleshooting Common Issues

- Vibration Problems: Recheck fastener tightness and alignment.

- Fastener Loosening: Apply the correct torque and use locking mechanisms.

- Corrosion: Use corrosion-resistant variants and apply protective coatings.

Future Developments in Fastener Technology

Advancements in materials science and manufacturing are paving the way for:

- Stronger Alloys: For higher stress tolerance.

- Smart Fasteners: Embedded sensors for real-time monitoring.

- Eco-Friendly Coatings: Reducing environmental impact.

Frequently Asked Questions (FAQs)

- Can Zuek fasteners be reused?

Yes, if they are not damaged or excessively worn. - Are Zuek fasteners suitable for electric vehicles?

Absolutely, especially in high-vibration areas. - What tools are needed for Zuek fastener installation?

Typically, a torque wrench and basic hand tools. - How do I prevent Zuek fasteners from corroding?

Use corrosion-resistant variants and apply protective coatings. - Can I use Zuek fasteners for custom machinery?

Yes, they are versatile and adaptable to various applications.

Conclusion

Zuek fasteners drive shafts are essential components in modern mechanical systems, offering unparalleled reliability, ease of maintenance, and resistance to harsh environments. By understanding their types, installation procedures, and maintenance requirements, you can ensure optimal performance and longevity in your applications. This guide aims to be your go-to resource for everything related to Zuek fasteners, helping you make informed decisions for your mechanical needs.

Other Articles

PS VL6400E: The Comprehensive Guide to Features, Performance, and More

Mastering the 2:59:52 – 3:01:61 Time Frame: A Comprehensive Guide

Evolution D5 Golf Cart Emblem Replacement STL

The Ultimate Guide to adsy.pw/hb5: Everything You Need to Know